Today, technology plays a vital role in all aspects of organizational operations, driven by evolving customer preferences. The automotive industry, like many others, is adopting modern technologies to deliver exceptional machines that prioritize driving experiences, design, and customer comfort.

Augmented reality (AR) stands out as a transformative force in this regard, bringing human imagination to life. It has already demonstrated its value across various industries, leading to significant growth in the market. According to a research report by Grand View Research, the global AR market was estimated to be USD 38.56 billion in 2022 and is projected to expand at a compound annual growth rate (CAGR) of 39.8% from 2023 to 2030.

AR not only revolutionizes customer engagements through virtual showrooms and vehicle configurators, enhancing the overall experience, but it also offers substantial benefits in automobile manufacturers’ operational processes. These include product design, production, prototyping, and more. Leveraging AR empowers automakers to accelerate idea deployment, visualize complex assemblies, and efficiently manage design iterations.

Faster idea deployment

One significant advantage of AR is how it speeds up the testing of concepts during the early stages of development. Usually, product and user experience concepts are visualized and developed through drawings and computer-aided design (CAD) modeling. However, when these ideas are translated into written or computer-screen representations, they often lose their connection to the real world’s scale and geographical context. At each stage of development, design-related delays are common for projects. AR solves this problem by allowing engineers to swiftly test concepts with a certain level of accuracy in a real-world setting. It enables engineers to pretotype (before prototyping) with greater ease since CAD models can be directly exported into AR software, replacing physical models with virtual ones.

Visualising designs efficiently

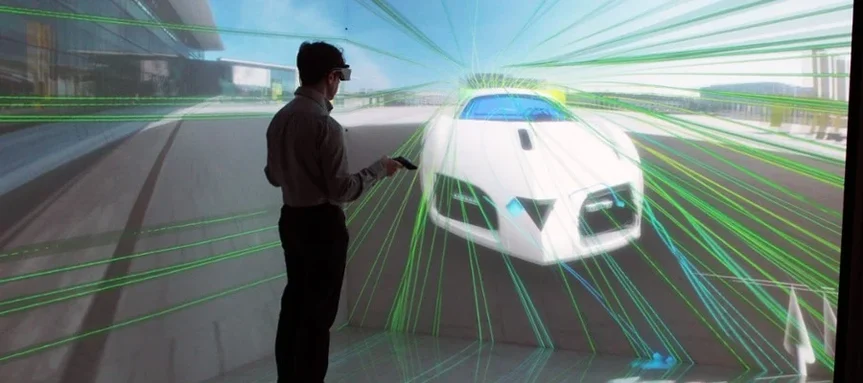

In addition to expediting idea deployment, AR is highly effective in visualizing designs efficiently. The design process is iterative, and modifications are inevitable. Managing multiple ideas and extensive vehicle assemblies can be complicated due to the involvement of various parts and departments. Augmented reality design, when combined with other prototyping methods, streamlines the development process. AR technology allows designers to view digital models and virtual prototypes in real-world settings, providing an immersive experience that enhances the design process. By overlaying digital information onto physical objects, designers can visualize and simulate the appearance and interaction of new components or design elements with existing vehicle structures. This simulation-driven design approach accelerates the overall design process, decreasing the time and cost associated with physical prototypes.

Overall, AR is revolutionizing the automotive industry’s design and operational processes, from idea generation to visualization and iteration management. Its ability to bridge the gap between imagination and reality significantly enhances efficiency, creativity, and cost-effectiveness in delivering exceptional automotive experiences.

Managing design iterations

Augmented reality (AR) plays a crucial role in optimizing and refining designs during the product development process. With the ability to import 3D CAD files into AR applications, designers can quickly transition their car assemblies and parts from their desktop screens into a natural environment. This allows for rapid review, amendments, and adjustments to concepts and alternatives. Additionally, AR integration enhances processes like Finite Element Analysis (FEA) and Computational Fluid Dynamics (CFD), enabling interactive evaluation and study of digital models. The result is accelerated iterative design cycles and the creation of outstanding vehicles. AR also facilitates animated simulations, allowing engineers and designers to envision long-term vehicle usage. This is essential for iterating designs and making swift adjustments to factors such as ergonomics, style, and component size. The use of AR not only increases productivity but also reduces errors and lowers the production cost of physical models.

Beyond the screen

One of the significant challenges in design and prototyping is the need to create physical models. AR addresses this challenge by overlaying new elements onto existing physical objects. This empowers automakers to deploy ideas quickly, visualize complex designs efficiently, and manage design iterations effectively. AR also enables seamless collaboration among designers on projects of any complexity, facilitating real-time changes during discussions.

AR systems transcend traditional screens, resulting in reduced development costs and durations for new designs. Leading automakers have already embraced AR technologies in their design and prototyping processes, and adoption is expected to grow rapidly. According to a report by Fortune Business Insights, the AR market size in the automotive industry is projected to reach USD 14.44 billion by 2028, with a compound annual growth rate (CAGR) of 18.1%. This growth is driven by the diverse use cases and increasing demand among top automakers.